An Industry First: Total Transparency

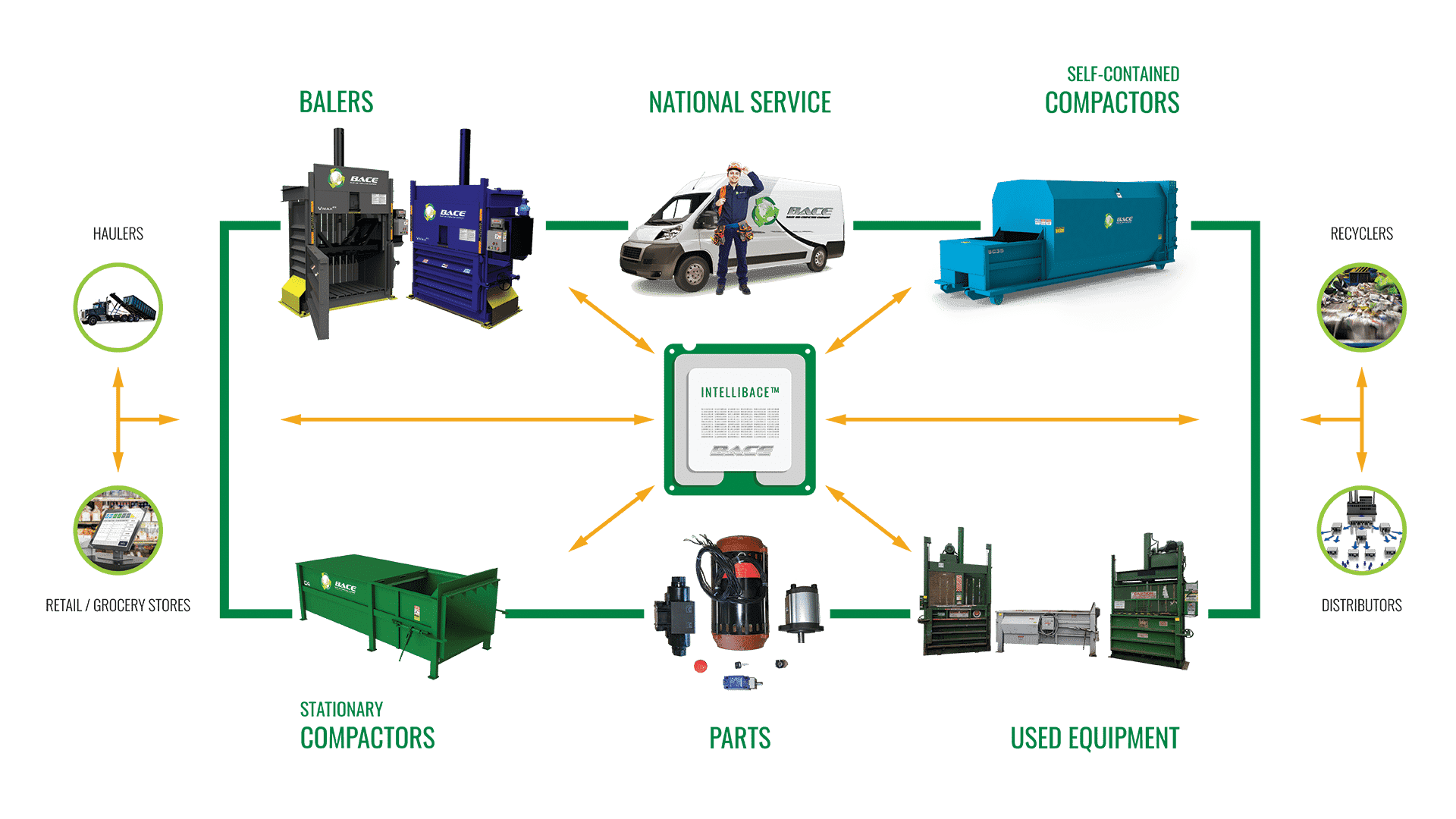

The BACE Ecosystem

Here's how it works:

BACE outfits any manufacturer’s baler or compactor with our patent-pending business intelligence and analytics platform, IntelliBACE™.

The platform will integrate your Waste and Recycling assets using cellular communication and deliver valuable, actionable data and insights to the cloud or to internal systems for your organization to manage and measure your Waste and Recycling program.

IntelliBACE™ delivers unmatched accountability and transparency, and is proven to help organizations increase revenue while decreasing expenses. The system also tracks usage data and provides alerts for preventative maintenance.

Every day, BACE uses its Ecosystem model to innovate new ways to disrupt and improve the Waste and Recycling Industry and deliver unmatched Transparency and Accountability.

“Doubt” doesn’t have to be a part of your waste and recycling transaction anymore.

Core IntelliBACE™

Architecture/Design

- Software as a Service (SaaS) - Cloud.

- Balers and Compactors are integrated under IntelliBACE™ – multi-equipment/single platform.

- Designed for Web and Mobile UI.

- Integrated Weight based scaling system – not Pressure Based – for improved accuracy.

- Sophisticated security model, including cellular technology, eliminating the risk to corporate networks.

- Predictive Analytics/AI.

Vertical Balers

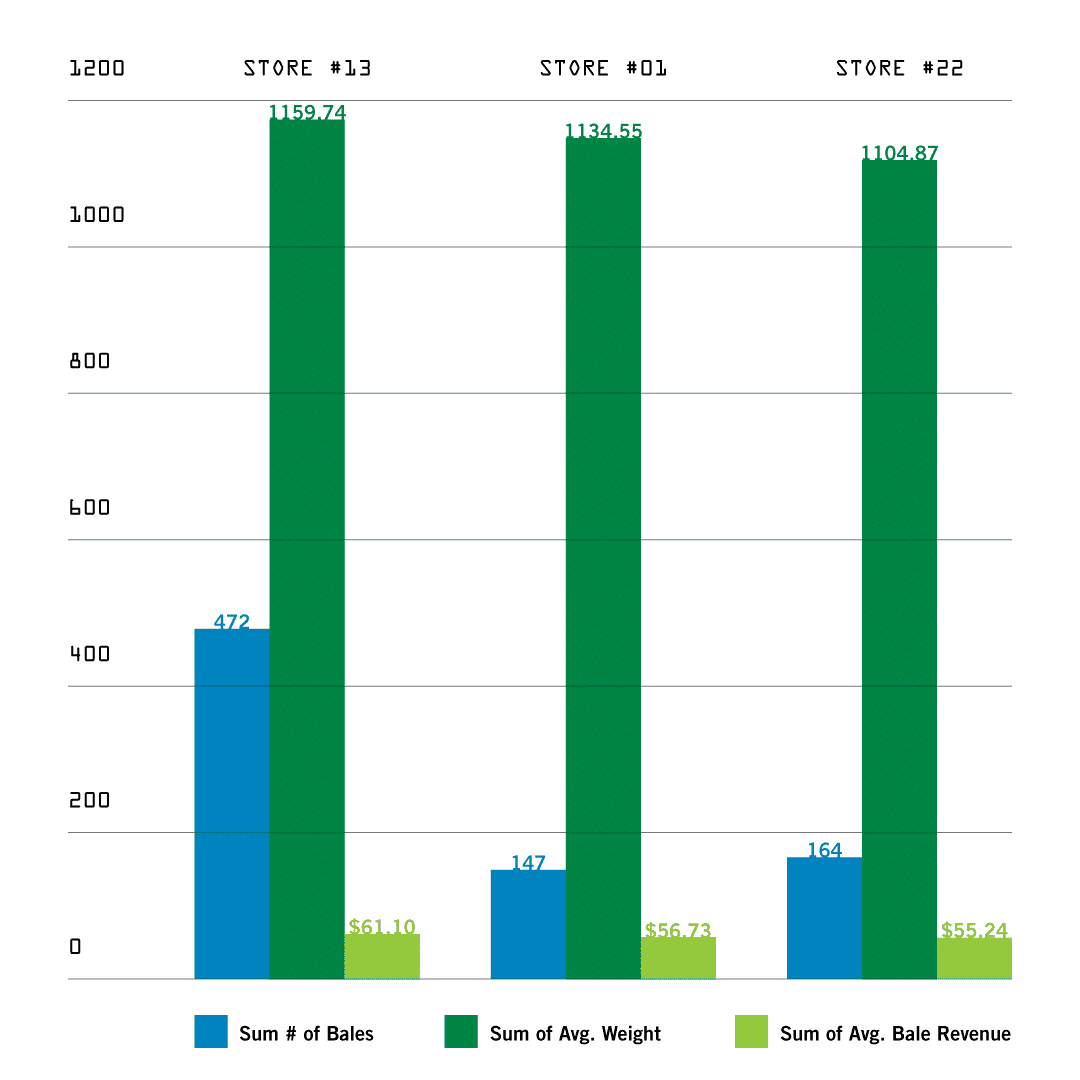

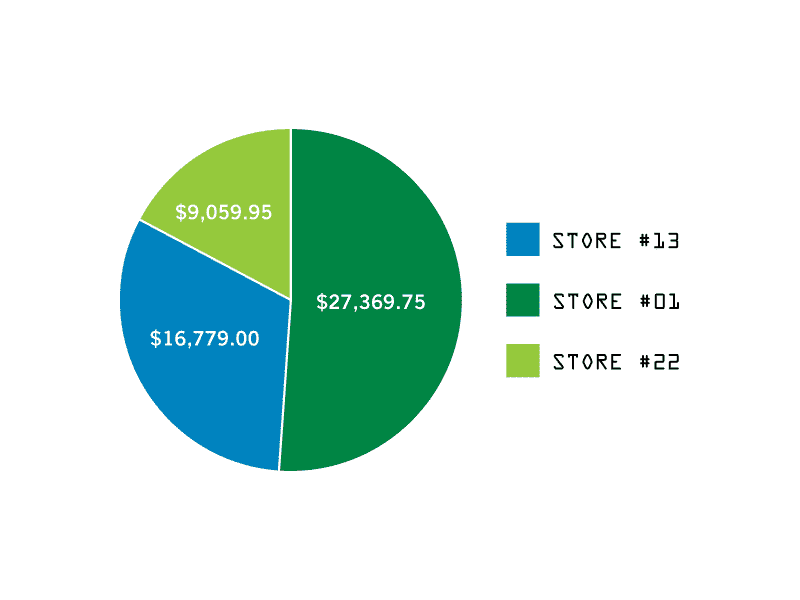

IntelliBALE™

- Available for ALL manufacturers Balers.

- Tracks exact weight of Bales produced - not pressure.

- Notifies recyclers when ready for pickup.

- Compares recycling trends by region, by location, and/or by shift.

- Tracks # of bales and revenue by location, region and more.

- Automatically notifies to reorder bailing wire.

- Reduces audit services by eliminating weight discrepancies.

- Tracks usage for proactive preventative maintenance.

- Service history at your finger tips.

- Remaining warranty coverage available in real-time.

- Data integration to corporate information systems.

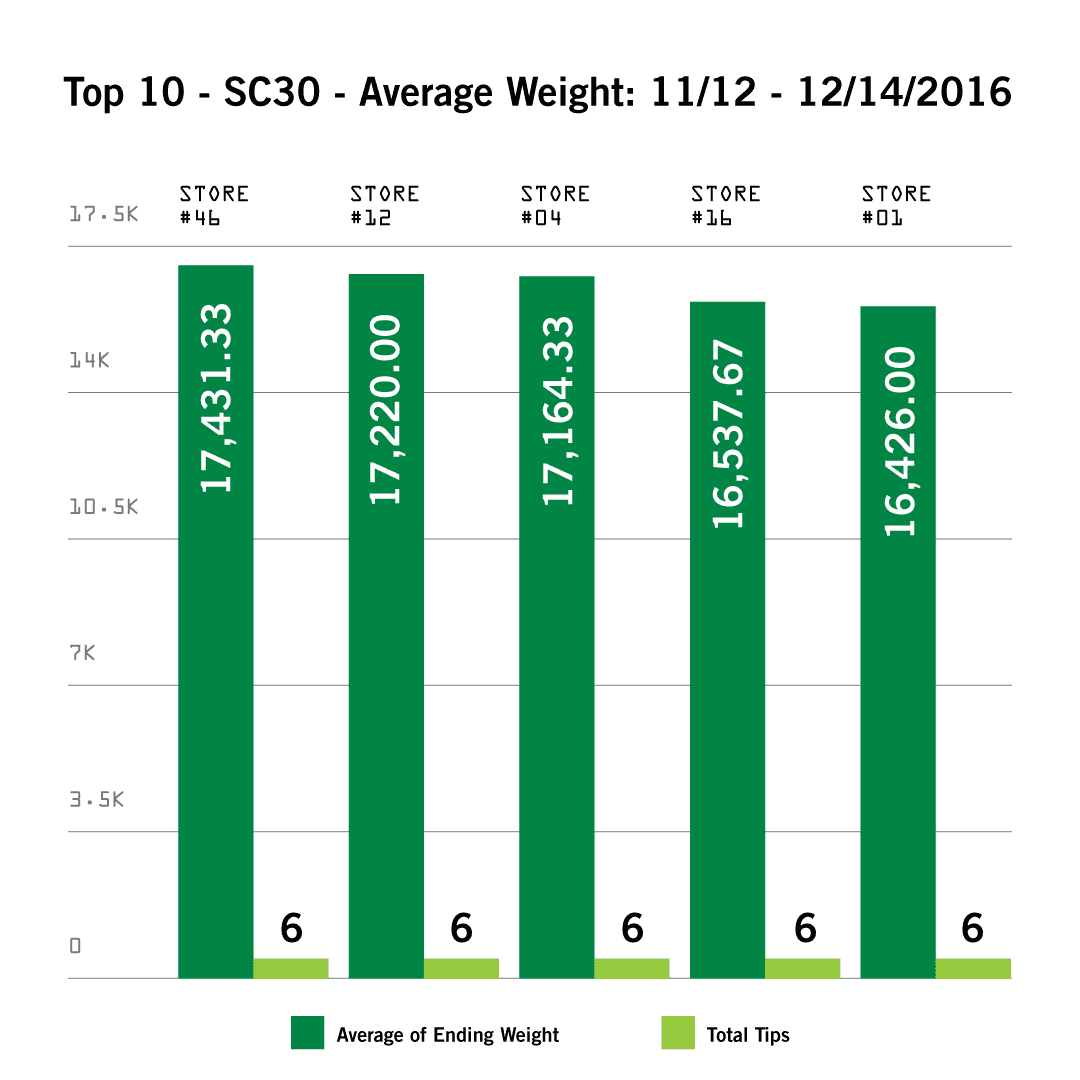

Compactors

IntelliPACT™

- Available for ALL manufacturers Compactors.

- Tracks exact weight of the Compactor contents - not pressure.

- Notifies haulers when x % full, ready for pickup.

- Reduces underweight tips.

- Reduces overweight tips.

- Compares waste trends by region and location.

- Tracks tip fees by region and location.

- Tracks usage for proactive preventative maintenance.

- Service history at your finger tips.

- Remaining warranty coverage available in real-time.

- Data integration to corporate information systems.